📣 Alcohol and Tobacco Tax and Trade Bureau (TTB) Investigation into Denatured Ethanol Heptane Purity

- SOLVENT DIRECT INC

- Feb 4, 2024

- 6 min read

Updated: Sep 19, 2025

The latest update on Solvent Direct's commitment to providing compliant products for extraction and the TTB investigation into non-compliant denatured ethanol CDA 12-A.

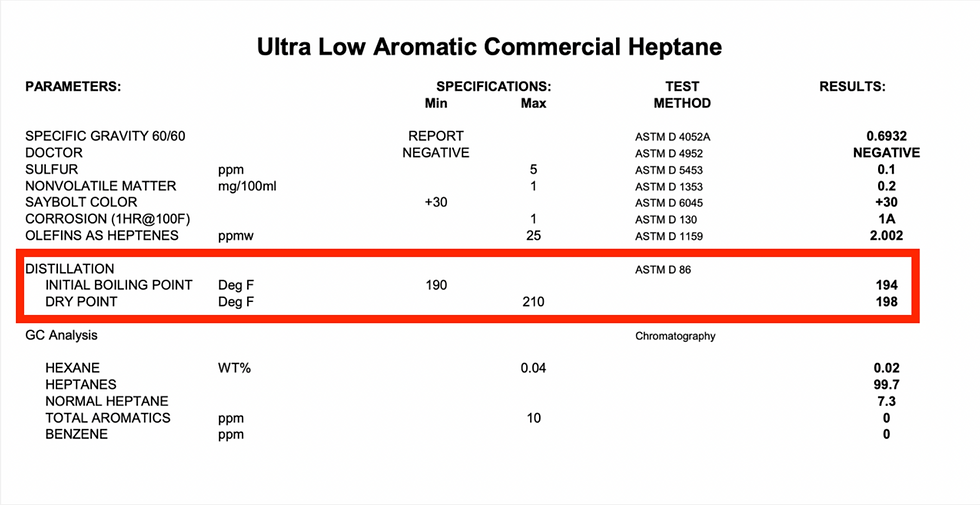

Recently, we were contacted by the Alcohol and Tobacco Tax and Trade Bureau (TTB) regarding an active investigation into a new ethanol blend found on the market which utilizes low purity heptane denaturants in CDA 12-A for extraction. Specifically, the TTB is looking at the distillation ranges of low purity heptanes used in the denaturing process outlined in 27 CFR § 21.112.

Following review with TTB Deputy Director

Tomika Moore, it has been affirmed that Solvent Direct n-heptane 99% variant used in 710 Solution CDA 12-A meets TTB's specifications. We understand the industry's desire for lower cost inputs and solutions for extraction supply, however here at Solvent Direct we believe in long term sustainability, compliance and success of our industry.

According to the TTB, certain distributors in the US are currently offering CDA 12-A to the extraction market with heptane that fails to meet the Federal TTB specifications for a proper distillation range. It is imperative to emphasize that deviations from the prescribed distillation range, specifically between 200-211°F, which fails to meet federal regulations and can introduce serious federal compliance, tax and safety concerns for end-users.

Using heptane with inconsistent distillation ranges poses potential dangers, compromising the intended properties and safety features of CDA 12-A. We strongly advise extractors and manufacturers to exercise caution and ensure that they purchase CDA 12-A only from reputable suppliers who adhere to the stipulated Federal TTB requirements, guaranteeing the highest standards of quality and safety in their products.

Penalties: Under 26 U.S.C. 5602, engaging in business as a distiller with intent to defraud the United States of tax is a felony punishable by up to 5 years in prison, a fine of up to $10,000, or both. Under 26 U.S.C. 5604(a)(1), transporting, possessing, buying, selling, or transferring any distilled spirit unless the container bears the closure required by 26 U.S.C. 5301(d) (i.e., a closure that must be broken in order to open the container) is a felony punishable by up to 5 years in prison, a fine of up to $10,000, or both, for each offense. Under 26 U.S.C. 5613, all distilled spirits not closed, marked, and branded as required by law and the TTB regulations shall be forfeited to the United States. In addition, 26 U.S.C. 5615(1) provides that unregistered stills and/or distilling apparatus also will be forfeited. Under 26 U.S.C. 5615(3), whenever any person carries on the business of a distiller without having given the required bond or with the intent to defraud the United States of tax on distilled spirits, the personal property of that person located in the distillery, and that person's interest in the tract of land on which the still is located, shall be forfeited to the United States. Learn more here.

Compliance: At Solvent Direct, we are proud distributors of CDA 12-A, a completely denatured alcohol blend consisting of compliant ethanol and n-heptane 99%. It is crucial to highlight that Solvent Direct n-heptane 99% utilized in this blend adheres strictly to Federal TTB requirements, necessitating a distillation range between 200-211°F. This specific requirement ensures compliance with regulatory standards.

As a National distributor of lab supply Engineered Specifically for Extraction and life-long industry advocates, we believe we have an obligation to maintain our commitment to purity standards. Our mission to address the most stringent requirements of quality, value, and service means we always will provide products that meet or exceed regulation. To this end, we would like to share a white paper from our vendor audit containing important information about our 710 Solution CDA 12-A quality assurance program.

Solvent Direct is proud to provide the following Comprehensive Analysis of Normal Heptane vs. Heptane: A Technical Perspective for Regulatory Bodies

Abstract: This white paper delves deeper into the nuanced distinctions between normal heptane (n-heptane) and heptane. It provides a detailed exploration of distillation ranges, purity standards, and their practical implications in advanced chemical applications, with a specific focus on essential oil extraction, and food and pharmaceutical-grade manufacturing. For the purposes of a basic understanding of the chemical formula, both n-heptane and heptane are the straight-chain alkane with the chemical formula H₃C(CH₂)₅CH₃ or C₇H₁₆. There are many isomers and enantiomers of the heptane molecule because there are seven carbon atoms in this molecule that can arrange in different forms making branched structures and chiral centers.

1. Distillation Ranges

Normal Heptane (n-heptane):

Exhibits a highly specific boiling point around 98-100°C, making it a reliable solvent in controlled environments.

This narrow distillation range enhances its suitability for processes demanding precise temperature control, such as chromatography and certain organic syntheses.

Heptane

Demonstrates a broader distillation range due to the presence of isomers, impacting its vaporization characteristics.

Heptanes, including Branched and Cyclical Heptane, Ultra Low Aromatic Heptane, IsoHeptane, NeoHeptane, and 3-Methylhexane.

Distillation conditions may need careful optimization to ensure consistent results, particularly in applications requiring high-purity solvents.

2. Purity Standards

Normal Heptane (n-heptane):

Recognized for exceptional purity, meeting, or exceeding industry standards.

Its reliability in chemical processes, including extraction and synthesis, stems from the absence of isomeric impurities found in alternative heptane formulations.

Heptane:

Varied purity levels linked to the composition of isomers present.

Depending on the application, users may need to consider these variations in purity, emphasizing the importance of meticulous sourcing and quality control.

3. Manufacturing Processes

Extraction:

Comprehensive studies have established that n-heptane is preferred in extraction processes due to its consistent composition.

Chemical engineers and skilled practitioners often choose n-heptane for its reliability in preserving the aromatic profile of botanicals.

The interplay between isomers in heptane might influence the extraction efficiency and aroma profile, demanding a thorough understanding of the specific botanicals involved.

Depending on the isomers, the recovery of heptane from a botanical extract can become extremely challenging.

Food and Pharmaceutical Grade Manufacturing:

Technical experts in pharmaceutical manufacturing acknowledge the significance of solvent purity in drug synthesis.

Instances exist (https://pubs.acs.org/doi/10.1021/acs.oprd.1c00005) where the choice between normal heptane and heptane has impacted the purity and yield of pharmaceutical products.

4. Neurotoxicity Concerns and Remediation Steps:

Heptane Neurotoxicity:

Chemical professionals are aware of documented cases linking prolonged exposure to heptanes, including isomers, to neurotoxic effects.

Remediation steps, such as advanced purification techniques or alternative solvents, may be considered in processes where minimizing neurotoxicity is paramount, specifically medicines derived from botanical sources.

Collaborative efforts among industry experts, researchers, and regulatory bodies are crucial to developing standardized safety measures addressing neurotoxicity concerns.

Conclusion: This expanded analysis provides a technical perspective on the differences between normal heptane and heptane, offering insights that should resonate with professionals in chemical applications. Acknowledging the importance of precise distillation, purity, and safety considerations is imperative for regulatory bodies to formulate informed guidelines that uphold industry standards and ensure the integrity of diverse manufacturing processes.

At Solvent Direct, our commitment to quality and compliance is unwavering. We understand the importance of providing products that meet the highest standards, especially in industries where precision matters.

We want to assure our customers that we are committed to using only compliant heptane. We have explored alternatives, but our priority is to maintain compliance. Any changes to the denaturant specifications would require a formal process with the TTB, and our clients can rest assured we will continue to offer the lowest cost products without compromise to quality or federal compliance.

For more details, you can refer to the TTB regulations here.

Your satisfaction, trust, and compliance are our top priorities. If you have any questions or concerns, we encourage you to reach out. Solvent Direct is dedicated to maintaining the highest standards, and we appreciate your understanding and continued partnership.

Thank you for choosing Solvent Direct – where quality meets compliance.

Solvent Direct stands as a trusted partner, ensuring the timely delivery of the lab supply extractors need, precisely when they need it. Through unwavering dedication to excellence, we strive to meet and exceed the most rigorous expectations of our valued clientele, providing unparalleled solutions in extraction lab supply.

Comments