West Coast CO₂ Shortages, Refinery Shutdowns and the Future of Dry Ice Supply

- Solvent Direct

- Jul 28, 2025

- 3 min read

Solvent Direct | July 2025

CO₂ Shortages Escalate Amid Refinery Shutdowns and Force Majeure Conditions

A wave of confirmed shutdowns across West Coast refineries—including Valero Benicia, Messer Keys, and Pixley Cogen—is placing immediate pressure on the national CO₂ supply chain. Simultaneously, a force majeure has been declared at several major CO₂ capture points, cutting off feedstock and triggering regional shortages, price volatility, and supply rationing.

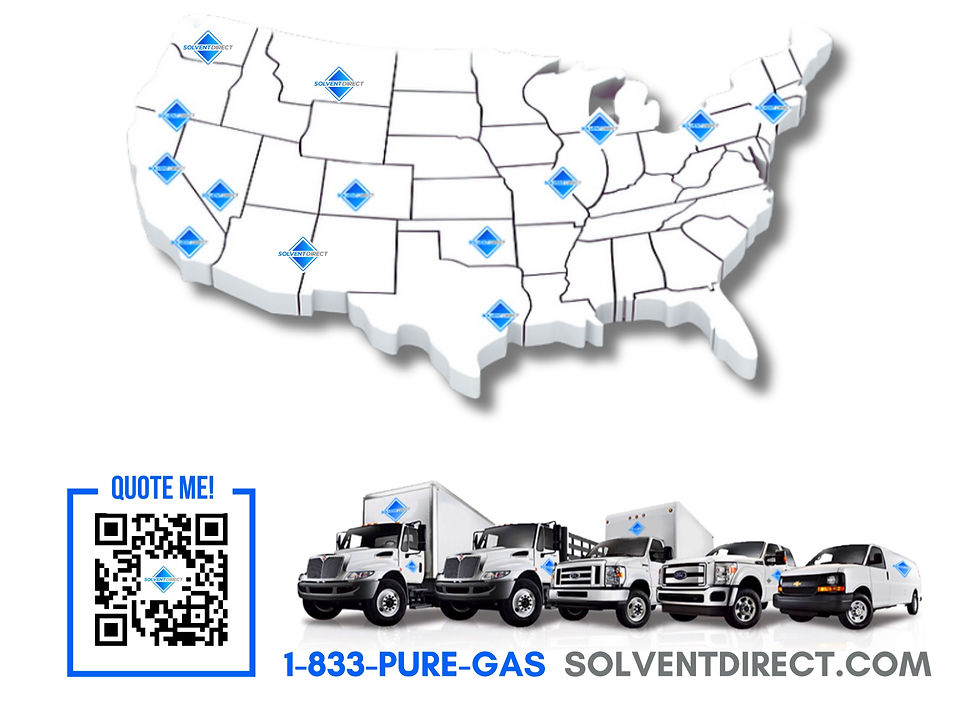

At Solvent Direct, we are actively mitigating these challenges, but the situation remains highly dynamic. Solvent Direct has leveraged its national network of liquid CO₂ supply and dry ice distribution to secure critical volumes and keep extractors extracting with ultra high density dry ice. While these force majeure circumstances are inevitable in a transitioning energy landscape, we appreciate our clients' patience and will continue to diligently monitor the situation and ensure a seamless and uninterrupted supply chain for our valued partners.

Refinery Shutdowns and CO₂ Feedstock Loss

Valero Benicia (Benicia, CA) Refinery CO₂ Capture

Crude refining capacity: 170,000 barrels/day

CO₂ capture/supply: ~200 metric tons/day (via on-site Linde facility for industrial reuse)

Type: Partial industrial gas capture; no full CCS

Represents ~9% of California’s refining infrastructure

Pixley Cogen Partners (Pixley, CA) Ethanol Plant CO₂ Capture

Daily capture: ~188 metric tons/day fossil CO₂

Type: Fossil combustion + biogenic emissions, no capture

Messer CO₂ Plant (Keyes, CA) CO₂ Capture from Ethanol Production

CO₂ capture/supply capacity: ~450 metric tons/day

Type: Fermentation gas recovery for food, beverage, and industrial use

These shutdowns significantly reduce daily capturable CO₂, creating downstream disruptions across food production, beverage carbonation, cannabis extraction, dry ice manufacturing, and other critical industries.

Major CO₂ producers across the country routinely face seasonal shutdowns, scheduled maintenance, and unexpected plant disruptions that severely limit CO₂ production. Under what the industry defines as a force majeure, these interruptions trigger immediate constraints on available supply. During such events, bulk producers implement allocation protocols—throttling supply lines and limiting the volume of CO₂ any distributor or bulk facility can procure. This creates a ripple effect of shortages across critical sectors reliant on consistent CO₂ access.

Solvent Direct’s Strategic Response is to always stay ahead of these shortages by leveraging our national distribution network, strategic procurement planning, and advanced technologies such as direct air capture. This forward-thinking approach ensures we continue to deliver an uninterrupted, high-quality CO₂ supply to our clients despite regional disruptions and force majeure conditions.

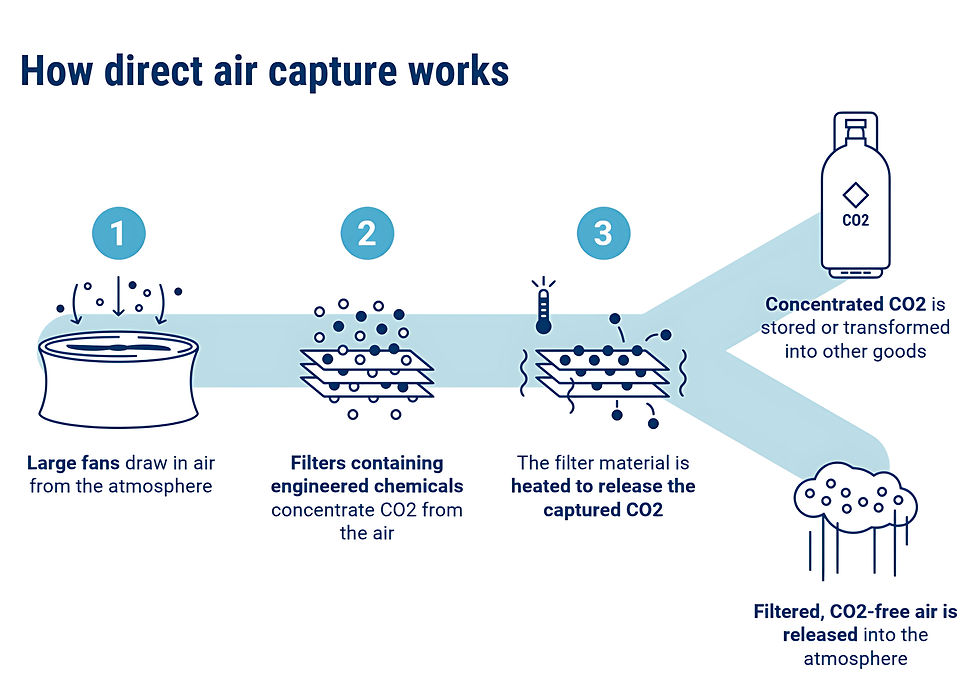

Direct Air Capture: The Next Frontier of CO₂ Supply

While traditional refineries are shutting down, new carbon removal technologies are emerging. Solvent Direct is proud to support Heirloom Carbon’s direct air capture (DAC) facility in Tracy, California—the first commercial DAC site in the U.S.

Captures up to 1,000 metric tons per year of atmospheric CO₂

Utilizes limestone-based mineralization

Fully powered by renewable energy

Backed by Stripe, Microsoft, and Frontier

Solvent Direct is working with DAC sites nationwide to bring this captured CO₂ into our national logistics network—expanding our capabilities with next-generation infrastructure.

Solvent Direct’s Multi-Layered CO₂ Supply Strategy

Solvent Direct was built for resilience. While others scramble during refinery outages, our infrastructure continues operating at full strength. Here’s how:

Diverse sourcing from ethanol, natural wells, petroleum, and DAC facilities

Ownership of CO₂ and dry ice production infrastructure

Diversified supply chain to source from several national producers

Nationwide logistics network for next-day delivery, even during supply chain disruptions

We Need Your Forecasts to Protect You

While we can move fast, we need visibility into your demand. During this force majeure and regional allocation tightening, planning is the key to preventing operational downtime and unnecessary cost increases.

Here’s how to help us help you:

Submit your 30/60/90-day forecasts to your Account Manager

Communicate any changes in production requirements and planning

Place orders early to lock in availability and minimize volatility

Solvent Direct: Future-Proofing CO₂ Supply Chains

The reality is clear: refinery-based CO₂ production is changing on the West Coast. The transition to renewable fuels, stricter regulations, and reduced petroleum output means the future of CO₂ depends on innovative infrastructure, supplier diversification, and strategic planning.

Solvent Direct leads the market in all three areas. We are sourcing from both traditional and emerging technologies—including DAC facilities—to protect your supply from regional disruption, industrial outages, and environmental constraints.

Already a customer? Connect with your Account Manager today to update your forecasts and prepare your supply strategy.

Not with Solvent Direct yet? Join the Solvent Direct Buyer’s Club today and gain access to the strongest CO₂ supply chain in the United States.

Contact Us www.solventdirect.com 1-833-PURE-GAS (1-833-787-3427)

Solvent Direct America’s Most Resilient CO₂ Supply Chain

Comments